Z7_89C21A40L06460A6P4572G3JN0

Inglés UdeA - Cabezote - WCV(JSR 286)

Inglés UdeA - Cabezote - WCV(JSR 286)

Z7_89C21A40L06460A6P4572G3JQ2

Signpost

Signpost

Generales

Z7_89C21A40L06460A6P4572G3JQ1

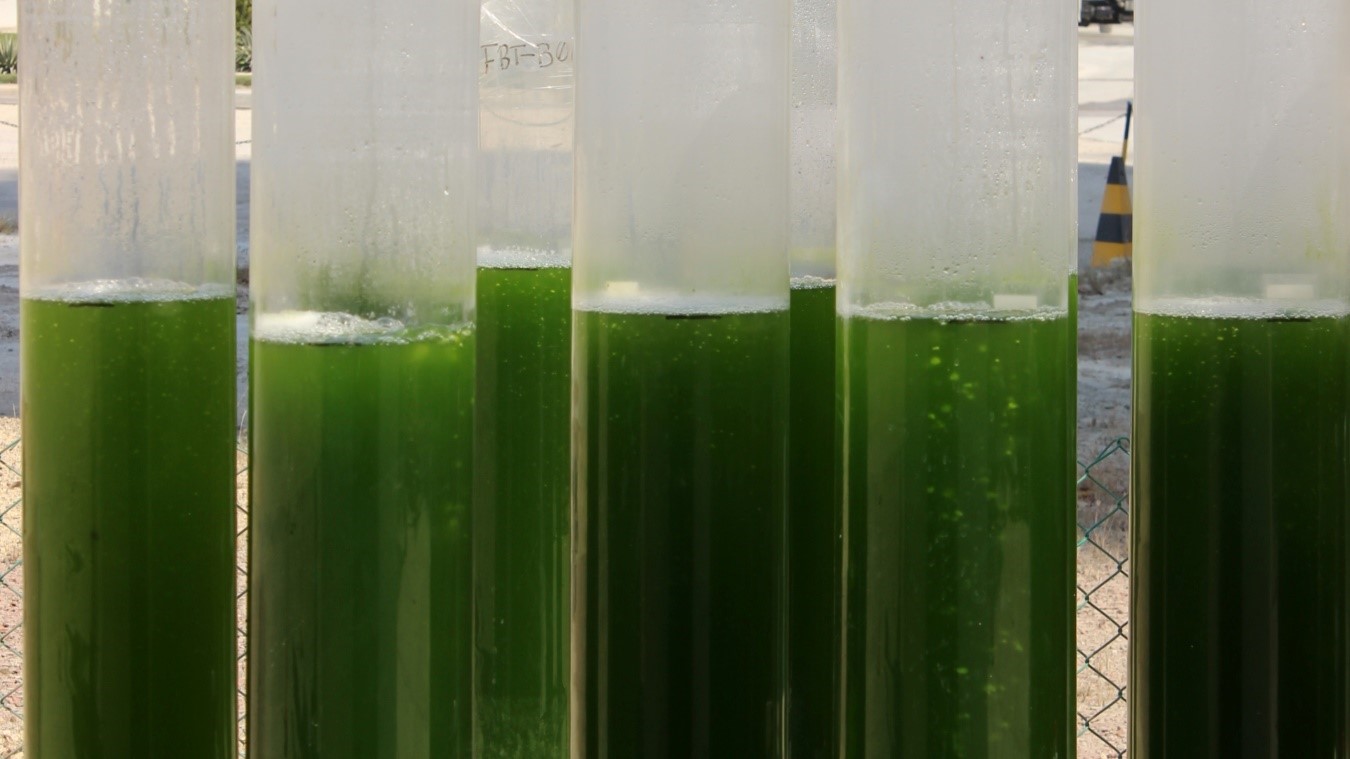

Biofuel produced from CO2 captured by microalgae

Biofuel produced from CO2 captured by microalgae

Z7_89C21A40L06460A6P4572G3JQ3

Portal U de A - Redes Sociales - WCV(JSR 286)

Portal U de A - Redes Sociales - WCV(JSR 286)

Z7_89C21A40L06460A6P4572G3J60

Portal U de A - Listado Interna Sin Menu - WCV(JSR 286)

Portal U de A - Listado Interna Sin Menu - WCV(JSR 286)

Z7_89C21A40L0SI60A65EKGKV1K57

Inglés UdeA - Iconos Footer - WCV(JSR 286)

Inglés UdeA - Iconos Footer - WCV(JSR 286)

Universidad de Antioquia | Vigilada Mineducación | Acreditación institucional hasta el 2022 | NIT 890980040-8

Recepción de correspondencia: calle 70 No. 52 - 21 | Apartado Aéreo 1226 | Dirección: calle 67 No. 53 - 108 | Horario de atención

Conmutador: [57 + 604] 219 8332 | Línea gratuita de atención al ciudadano: 018000 416384 | Fax: [57 + 604] 263 8282

Peticiones, quejas, reclamos, sugerencias, denuncias, consultas y felicitaciones

Política de tratamiento de datos personales

Medellín - Colombia | Todos los Derechos Reservados © 2018

Recepción de correspondencia: calle 70 No. 52 - 21 | Apartado Aéreo 1226 | Dirección: calle 67 No. 53 - 108 | Horario de atención

Conmutador: [57 + 604] 219 8332 | Línea gratuita de atención al ciudadano: 018000 416384 | Fax: [57 + 604] 263 8282

Peticiones, quejas, reclamos, sugerencias, denuncias, consultas y felicitaciones

Política de tratamiento de datos personales

Medellín - Colombia | Todos los Derechos Reservados © 2018